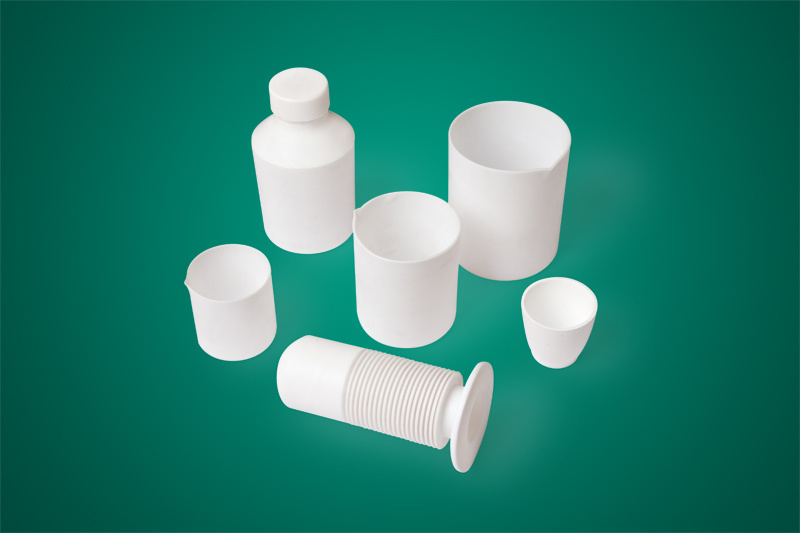

Precision PTFE Components Deliver Performance Across Industries

Time:2025-08-11 16:53

Quality PTFE shaped parts from China components are gaining prominence as specialized solutions for demanding mechanical and chemical applications. These custom-engineered parts leverage PTFE's unique properties to solve specific engineering challenges where standard materials would underperform. Their growing adoption reflects industry's need for components that combine chemical resistance with reliable mechanical performance.

The extremely low friction coefficient of quality PTFE shaped parts from China components makes them ideal for moving mechanical applications. Unlike metal alternatives that require constant lubrication, these parts provide lasting performance in dry conditions. Manufacturers of packaging machinery, food processing equipment, and automotive systems value how these components reduce wear while eliminating contamination risks from lubricants. The self-lubricating nature ensures consistent operation in environments where maintenance access is limited.

Superior sealing performance distinguishes quality PTFE shaped parts from China products in fluid handling systems. Their ability to maintain compression set under varying temperatures and pressures makes them preferred choices for gaskets, seals, and flanges in chemical processing. The material's chemical inertness ensures long-term integrity when exposed to aggressive media, outperforming rubber and composite alternatives that degrade over time. These characteristics significantly extend service intervals in pumps, valves, and piping systems.

The dimensional stability of quality PTFE shaped parts from China components proves valuable in precision applications. Unlike some plastics that warp or creep under load, PTFE maintains its shape across wide temperature ranges from -180°C to +250°C. This thermal stability makes the parts reliable for semiconductor manufacturing equipment, laboratory instruments, and aerospace components where precise tolerances must be maintained despite environmental fluctuations.

As industries face increasingly stringent performance requirements, quality PTFE shaped parts from China continue to evolve. Manufacturers now produce complex geometries including custom bushings, bearings, and insulating components tailored to specific equipment needs. The combination of chemical resistance, thermal stability, and self-lubricating properties positions these precision parts as smart solutions for challenging applications where conventional materials reach their limits. Their growing use across industrial sectors demonstrates how specialized polymer components can enhance equipment reliability while reducing maintenance demands.

Recommended news

Good News | WOTE Holdings Awarded Wind ESG Rating A, Demonstrating Sustainable Development Strength!

2025-07-10

Major Breakthrough! WOTE's Chongqing Base LCP and PEEK Projects Officially Commence Production

2025-05-23

Unlocking the Potential of Liquid Crystal Polymer Resin: A Game Changer in Advanced Materials

2025-08-12

Headquarters business contact

Home / About us / Product / Technology / News / Performance Express / Join us / Contact

Links: Shanghai WOTE Huaben